Staff

The team of the LLC «O’ZJIHOZBUTLASH» is a unique fusion of old-school people with a thorough approach to the development of production technology with the younger generation using modern information technologies, materials, and working methods.

More than 70 people are involved in the production, each of whom is fully dedicated to their work to ensure a high collective result.

Professional development of personnel is regularly carried out, which aims to further improve the professional skills of production and management personnel, as the main factor in improving the quality of products.

Production Premises

The LLC «O’ZJIHOZBUTLASH» is equipped with all the necessary production infrastructure and is located in the industrial zone of the city of Tashkent on an area of 1.95 hectares.

The total area of the production site is more than 1800 m2. At the same time, this area is a “clean room” of class ISO8 (100,000).

Packaging of finished products after finishing washing is carried out in a room of class ISO 7 (10,000).

“Clean rooms” are designed, built, commissioned and operated in accordance with all the requirements of good manufacturing practice (GMP).

Equipment

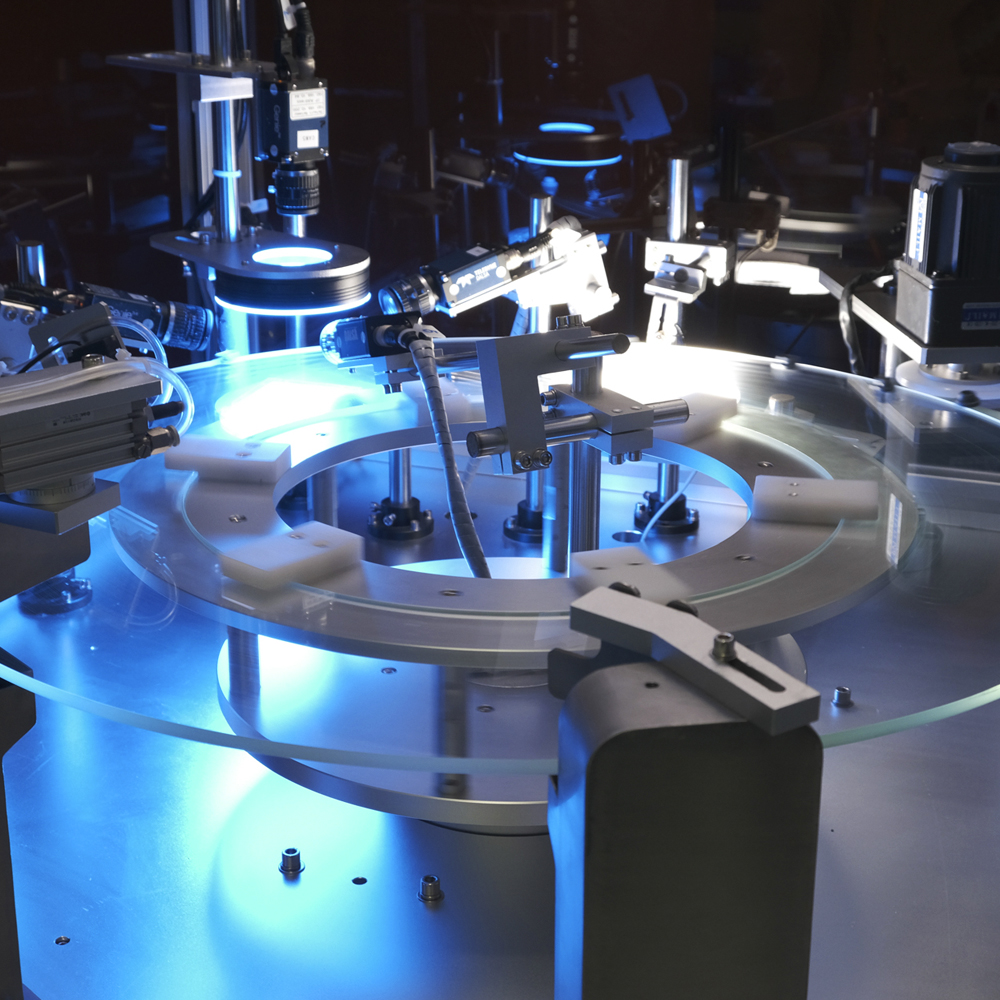

All our products are constantly monitored with the help of machine vision systems, which ensures confidence in the quality of the finished product and the absence of defects.

The company has installed equipment from the world’s leading manufacturers: the United States, Germany, France, Korea, and China. When choosing the equipment, we were guided by its technical and technological novelty, the presence of computer control, adaptability to work in “clean rooms”, energy efficiency and environmental friendliness.

Due to the high energy intensity of the products, the company’s activities are carried out in accordance with the spirit of the international standard ISO 50001 – Energy Management System.

In order to improve the efficiency of the use of raw materials, reduce losses and costs, the company is working on the implementation of the International Standard ISO 14001-Environmental Management System.

Technology

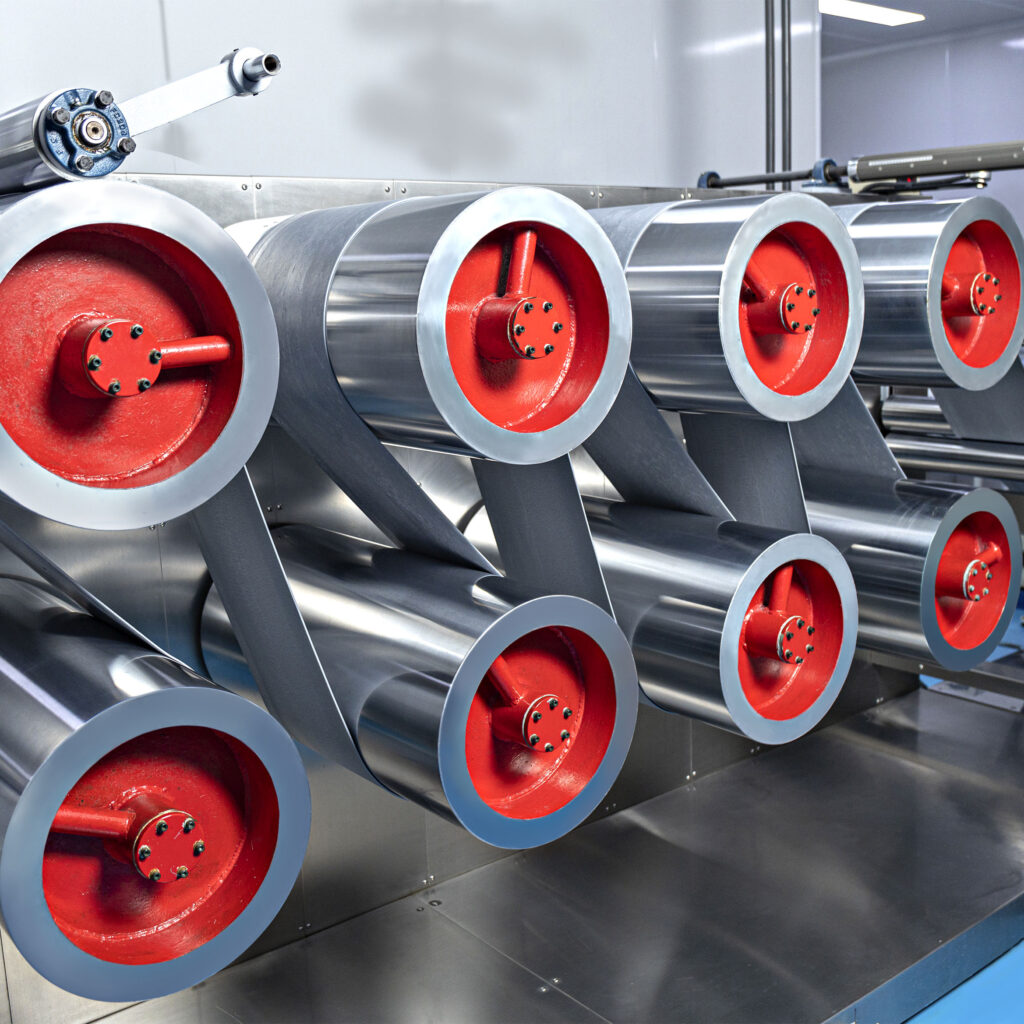

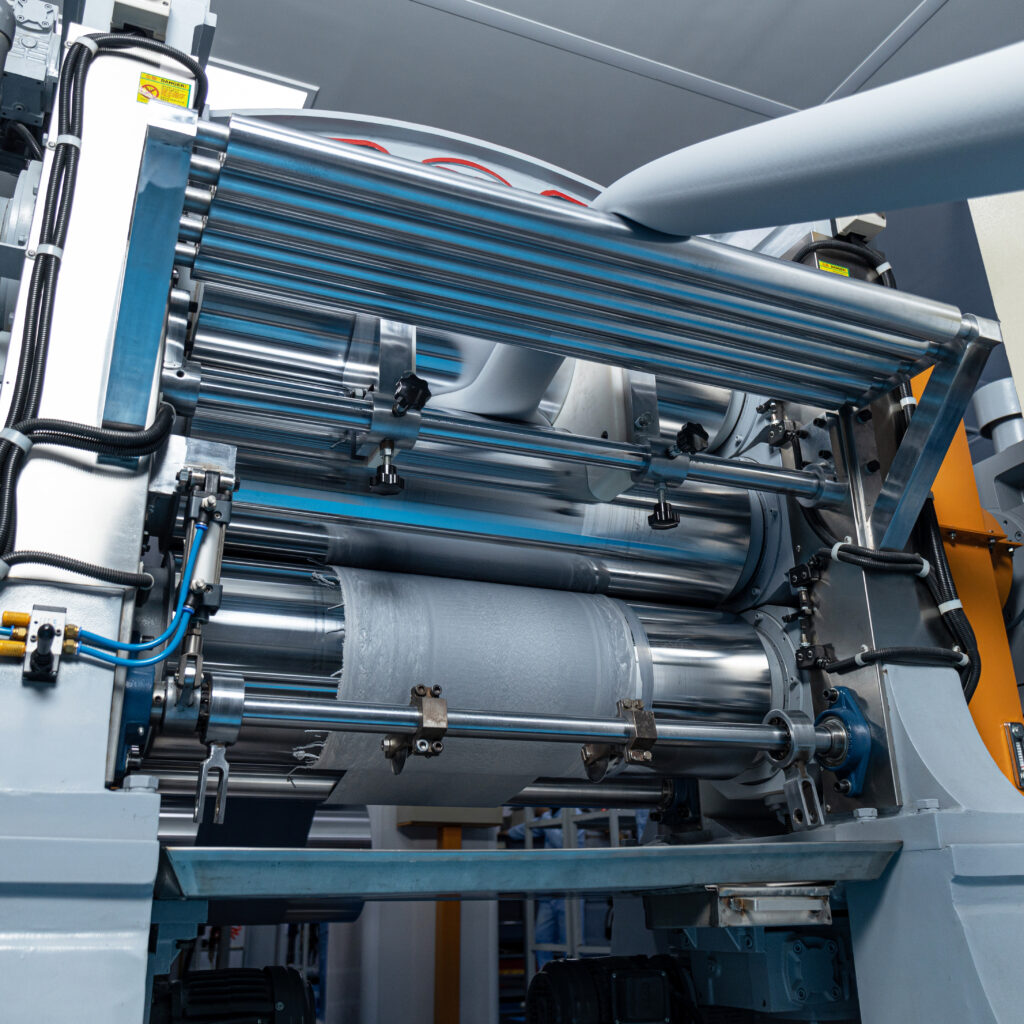

The production of the rubber mixture is carried out in two stages, in a closed mixer and on rollers. This type of production allows you to achieve uniformity of all manufactured rubber batches, as well as to intensify the process.

The design of washing machines is arranged in such a way that the unloading of products ready for sterilization is carried out in another room, of a higher class of cleanliness, where the products are packed both in plastic bags and in bags for sterilization.

Currently, the organization can produce simple aluminum caps and combination caps with an opening indicator. We have all the necessary equipment for this type of activity: exhaust presses, injection molding machines, assembly machines for each cap size.

Quality Control

All our products are constantly monitored with the help of machine vision systems, which ensures confidence in the quality of the finished product and the absence of defects.

In addition to industrial equipment, the company also has laboratory equipment. Thanks to this, not only is each batch of incoming raw materials checked before it is put into production, but also the development and testing of rubber compounds according to any customer’s wishes.

Our laboratory coordinates all stages of production: control of raw materials of each batch of manufactured rubber compound, semi-finished products, as well as finished products in accordance with all the requirements of international standards GOST, ISO, as well as European, American and other world pharmacopoeias.